And finally, the adaptability of those machines to varied element sorts and sizes underscores their versatility, accommodating intricate PCB designs in addition to a wide array of parts easily.

We are going to offer you the shipping and delivery expenses and you may pick the 1 which is considered the most handy and helpful for you personally.

The ND4 pick and place machine is the result of our decades worthy of of experience creating and manufacturing most effective-in-class SMT products. We've been obsessed with general performance and that’s why we additional several “massive machine” options of our larger models within the ND4.

Remarkable Throughput: These machines are ideal for large-quantity production, as they are able to simultaneously work on 4 PCBs, considerably growing the output.

The cost of a SMT pick and place machine could vary considerably depending on its measurement, options, and capabilities. Although Expense really should not be the sole Consider determining on an SMT pick and place machine, it is an important a single to consider.

This short article has several difficulties. Remember to aid strengthen it or focus on these concerns around the discuss web site. (Learn the way and when to eliminate these messages)

Definition and Goal: SMT (Area Mount Technology) pick and place machines are necessary equipment in electronics producing, automating the placement of parts on to printed circuit boards (PCBs) to boost performance and precision.

Substantial Dependability: Engineered for longevity and consistent effectiveness, our machines lower downtime and increase operational performance.

Usually when PCB’s are designed the software employed has the chance to output many forms of data. The most common is ‘Gerber’ facts which can be a standard electronics industry file structure which is used to communicate layout info to PCB brands - gerber information is often seen on the net in this article.

To attain a sustainable society, we commit to strive to be an organization that earns society's belief.

The NeoDen four SMT placement machine incorporates the next technological options which are Generally only readily available in SMT placement devices of Substantially bigger Value: –

Producers that use pick and place automation are sometimes in a position to lessen their creation prices whilst enhancing performance and accuracy. The lowered overhead and improved productiveness lead to amplified profits for companies, allowing for them to better contend of their respective markets.

Component Dimension Verification: Laser measurement can be employed to verify the size of parts, guaranteeing they meet precise pcb pick and place machine requirements. This is often essential for parts with precise dimensions specifications.

Part Orientation: Vision devices use cameras to capture images of factors just before placement. These pictures are analyzed to find out the orientation of factors, making sure They may be the right way aligned ahead of currently being picked up by the placement head.

Brandy Then & Now!

Brandy Then & Now! Daryl Hannah Then & Now!

Daryl Hannah Then & Now! Nadia Bjorlin Then & Now!

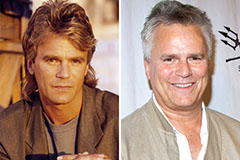

Nadia Bjorlin Then & Now! Richard Dean Anderson Then & Now!

Richard Dean Anderson Then & Now! Peter Billingsley Then & Now!

Peter Billingsley Then & Now!